Gallium-68 in Nuclear Medicine: Personalized

PET Imaging and GMP-Compliant Production

The development of Gallium-68 (Ga-68)–based radiopharmaceuticals has significantly advanced the field of nuclear medicine, enabling a more targeted and personalized diagnostic approach. While the first Ga-68 generators were introduced between the 1950s and 1970s, the clinical application of Ga-68 labeled compounds has gained prominence over the past two decades, particularly in positron emission tomography (PET) imaging.

When Ga-68 is complexed with specific targeting molecules, such as PSMA inhibitors for prostate cancer or somatostatin analogs for neuroendocrine tumors, the resulting radiopharmaceuticals provide high-contrast, high-resolution images that reflect the biological characteristics of the disease. These agents enable precise detection and staging by binding selectively to molecular targets overexpressed on tumor cells.

Such molecular imaging plays a crucial role in clinical decision-making, supporting the selection of patients for subsequent therapeutic procedures. In the context of theranostics, although Ga-68 is purely diagnostic, it serves as a companion imaging agent to therapeutic radionuclides such as Lutetium-177, Actinium-225, or Terbium-161, which are labeled to the same targeting molecule. This approach ensures consistency between the diagnostic and therapeutic phases, contributing to highly personalized and effective treatment strategies.

From a safety perspective, the handling and preparation of Ga-68–based radiopharmaceuticals require specialized devices and infrastructure. While product integrity is crucial, particular attention must be given to radiation protection for the operator. Shielded systems, sterile environments (e.g., classified laminar flow hoods are essential to minimize radiation exposure, ensure radiochemical purity, and maintain injectability standards for patient safety.

FHR1-50-LAF

Shielded Radiochemistry Fume Hood with Laminar Flow

Combines 50 mm lead shielding with vertical laminar flow compliant with Class A (EEC-cGMP) standards, ensuring both operator safety and product sterility. The structure is made of AISI 316L stainless steel with a Mirror-Bright finish and continuous TIG welds, allowing for fast and effective decontamination. A shielded sliding front window provides secure access to the working area, while integrated HEPA and activated carbon filters, monitored by pressure gauges, ensure optimal air filtration and containment.

BH Series

Biohazard Class A Hood

Designed for the sterile and shielded handling of radiopharmaceuticals. Fully compliant with Class A (EEC-cGMP) and EN12469 standards, it offers a safe and controlled environment for nuclear medicine and PET applications. The unit features a fully shielded Ga-68 generator compartment with 50 mm lead, sealed capillary connections, and a practical front drawer for safe and ergonomic generator loading. The spacious work area, made of AISI 316L stainless steel, supports easy decontamination and is equipped with laminar downflow and a shielded sliding glass window for optimal operator protection.

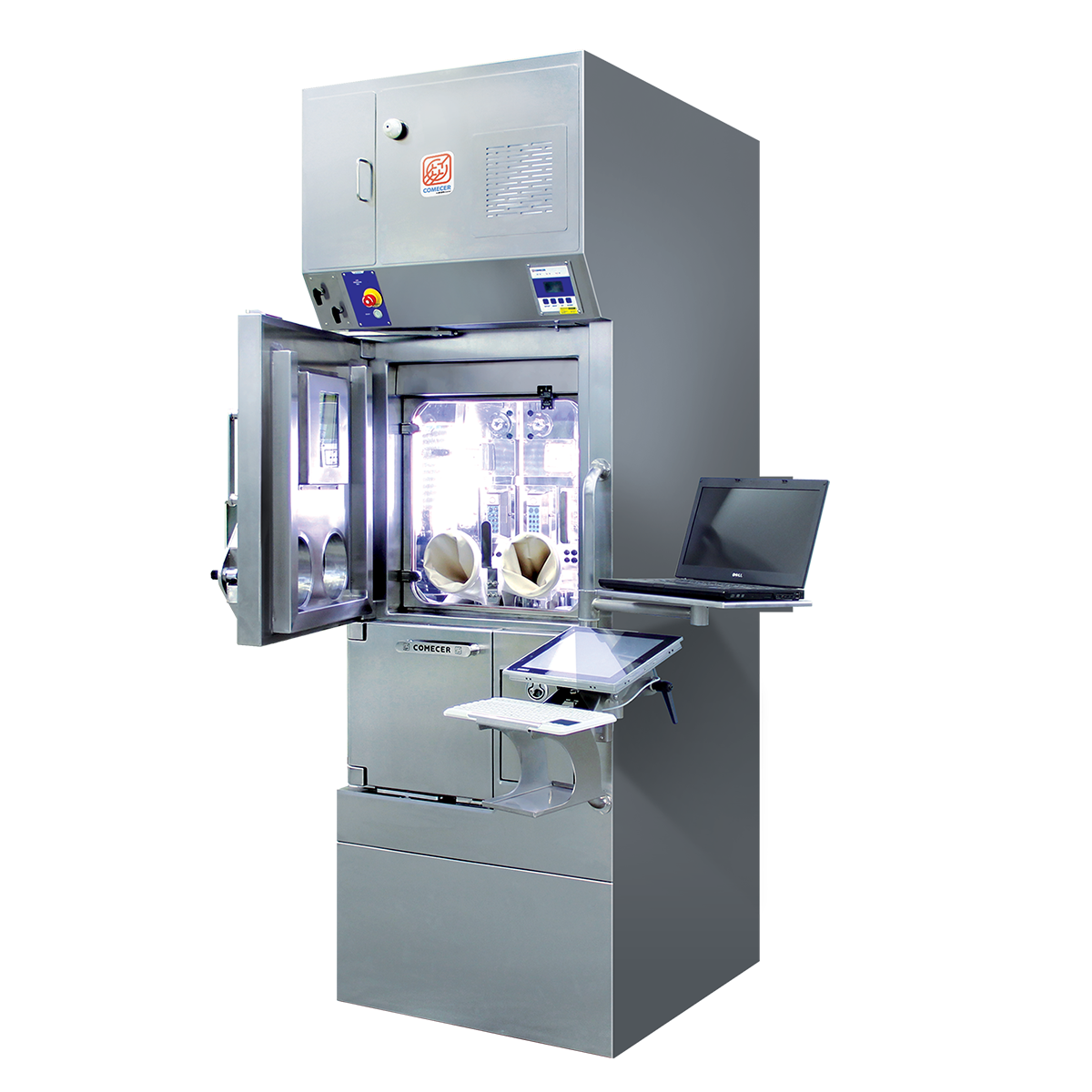

Thecla

Shielded Isolator with Integrated Dispensing System for Syringes

The sterile dispensing of radiopharmaceuticals, such as Ga-68, in full compliance with GMP standards. It features a laminar flow main chamber to ensure product sterility, an IBC dose calibrator capable of handling up to 2 Ci, and a syringe unloading system that safely transfers used syringes into shielded containers. Engineered for confined pharmaceutical spaces, THECLA guarantees optimal operator protection while maintaining a controlled sterile environment.

Musa 68Ga

Shielded Isolator for Gallium-68 Synthesis and Dispensing

Flow isolator specifically designed for the manipulation, synthesis, and dispensing of radiopharmaceuticals such as Ga-68, fully compliant with cGMP standards. Its Class A main chamber guarantees sterile conditions, while optional configurations allow integration of synthesis modules, fractionators, and dose calibrators.

Equipped with advanced shielding, ventilation, and decontamination features, MUSA 68Ga ensures maximum safety for both the product and operator, making it ideal for compact nuclear medicine environments.

GMP standards are guaranteed

All of our fume hoods and dispensers are manufactured according to GMP standards. This essential certification guarantees that each product is produced under controlled, reproducible and validated conditions, ensuring quality, purity and safety.

This is particularly critical when the product is administered to vulnerable patients and used for both clinical decision-making and targeted therapy. Furthermore, GMP compliance supports full traceability and regulatory accountability, which are indispensable in translational research and routine clinical use.

Fill out the form to downlod the

PDF document

Need expert advice, want to speak with one of our specialists, or simply interested in our solutions?

Get in touch today with your local Area Sales Manager.