The role of Gallium in Radiopharmacy

Discover how Gallium can be used in both diagnostic and therapeutic areas of human medicine

Gallium is used in both diagnostic and therapeutic areas of human medicine.

Isotopes 67Ga and 72Ga are used as radioactive markers in the diagnosis of certain cancers, such as lymphomas, because of gallium’s predisposition to accumulate more at sites of active proliferation.

68Ga with a half-life of only 68 minutes, inconvenient for transport is extracted and used for certain positron emission tomography nuclear medicine diagnostic procedures, where the radioisotope’s relatively short half-life and emission of positrons for creation of 3-dimensional PET scans, are useful. 68Ga can be produced with a cyclotron (solid or liquid target) or a generator.

A germanium-68/gallium-68 generator is a device used to extract the positron-emitting isotope 68Ga of gallium from a source of decaying germanium-68. The parent isotope 68Ge has a half-life of 271 days and can be easily utilized for in-hospital production of generator produced 68Ga.

germanium-68/gallium-68 generator functioning: the stationary phase is either metal-free or alumina, TiO2 or SnO2, onto which germanium-68 is adsorbed. The use of metal-free columns allows direct labeling of 68Ga without pre-purification, hence making production of gallium-68-radiolabeled compounds more convenient. The mobile phase is a solvent able to elute (wash out) gallium-68 (III) (68Ga3+) after it has been produced by electron capture decay from the immobilized (absorbed) germanium-68. Currently, such 68Ga (III) is easily eluted with a few mL of 0.05 M, 0.1 M or 1.0 M hydrochloric acid from generators using metal-free tin dioxide or titanium dioxide adsorbents, espectively, within 1 to 2 minutes. With generators of tin dioxide and titanium dioxide-based adsorbents, there once remained more than an hour of pharmaceutical preparation to attach the gallium-68 (III) as a tracer to the pharmaceutical molecules DOTATOC or DOTA-TATE, so that the total preparation time for the resulting radiopharmaceutical is typically longer than the 68Ga isotope half-life. This fact required that these radiopharmaceuticals be made on-site in most cases, and the on-site generator is required to minimize the time losses; unless there is the possibility to produce big amount of 68Ga, for example with a solid target. In this case with a production of 1Ci or more of 68Ga).

In case of 68Ga production with a 68Ge generator, to avoid exposures to the operators

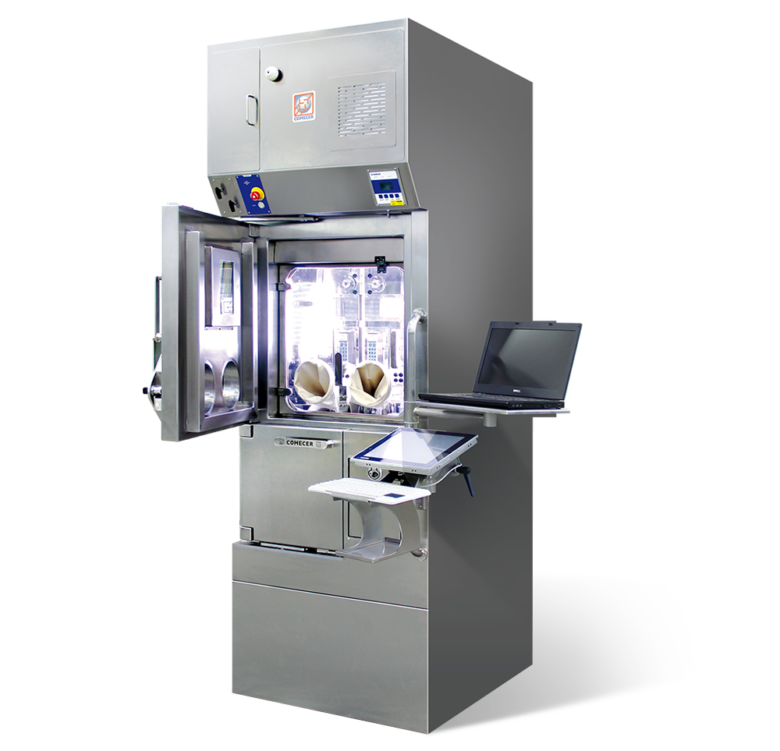

Comecer proposes this hot cell:

MUSA 68Ga, Shielded Isolator for Gallium-68 Synthesis and Dispensing

This hot cell has a shielded comportment for the generator only! It will be then connected to a synthesis module for the labeling procedures, inside the main box where it can be possible to measure and even dispensing the final labelled radiopharmaceutical.

Another hot cell can be:

THECLA, Shielded Isolator with Integrated Dispensing System for Syringes

A hot cell with a special compartment for the generator, enough space to accommodate the most common synthesis module (to label the gallium milked from the generator) and even a syringe dispensing system integrated (to dispense the radiopharmaceutical).

68Ga can also be produced directly on the cyclotron via the 68Zn(p,n)68Ga nuclear reaction, with various production routes. Depending on the production technique, cyclotron 68Ga yields are typically one to several orders of magnitude greater than currently available 68Ga/68Ge generators. Significant development has been undertaken in the field of liquid targets for 68Ga production. Aqueous solutions of isotopically enriched zinc-68 (68Zn) zinc nitrate in nitric acid were subjected to proton bombardment producing 9.85 ± 2.09 GBq at EOB.

Alternatively, solid targets using electroplated or pressed metal 68Zn powder have been used, where 68Zn is electroplated or pressed onto metallic target backings. Post-irradiation, the metallic 68Zn is dissolved for chemical separation and 68Ga purification. An alternative target system combining irradiation and dissolution has recently been developed that aims to address the limitations of solid and liquid targetry.

Liquid 68Zn target solutions are prepared by dissolving isotopically enriched 68Zn metal or 68Zn oxide in nitric acid to produce [68Zn]Zn(NO3)2 . It was found that irradiating ZnCl2 leads to a significant pressure buildup of hydrogen and oxygen resulting from beam-induced radiolysis of the target solution. Target assemblies can utilize a combination of helium and water cooling to remove heat, with the target solution and cooling fluids separated by aluminum and niobium foils. Targets are typically irradiated at energies of 12–14 MeV up to 45 µA beam current with 68Ga yields dependent on the target pressure and concentration of 68Zn solution, yielding up to 9.85 GBq after a 60 min irradiation. While irradiating at higher beam energies increases 68Ga yield, it increases production of the 67Ga radionuclidic impurity, so irradiating at a lower energy of ~ 12 MeV improves radionuclidic purity through avoiding onset of the 68Zn(p,2n)67Ga reaction. However trace levels of undesired isotopic impurities (0.1% 66Zn and 0.48% 67Zn) present in highly enriched 68Zn (99.3%) lead to unavoidable production of 66Ga and 67Ga from the 66Zn(p,n)66Ga and 67Zn(p,n)67Ga reactions, respectively.

Solid 68Zn targets are prepared by either by electroplating or pressing 68Zn powder and irradiating at the same beam energies as liquid targets to achieve similar radioisotopic purity. Electroplated targets are produced using platinum, gold, or silver target backings, with the desired cyclotron beam-spot on the target backing immersed in a [68Zn]ZnCl2 electroplating solution to deposit 40–250 mg 68Zn metal on a 7–12 mm target beam-spot.

Targets are then irradiated at currents up to 35 μA beam current at from 12 to 14.5 MeV , yielding up to 60.9 GBq after a 60 min irradiation. Similar to liquid targets, solid targets use helium and water cooling, with helium cooling provided across the front of the target assembly, while water cooling flows along the target backside. It is important to achieve an even cyclotron beam distribution across the 68Zn target material to avoid excessive heat loads concentrated on small areas of the target. For both electroplating and pressed powder targetry, an optimal 68Zn pellet thickness can be selected based upon production requirements, with thicker 68Zn targets yielding greater 68Ga for a given irradiation time at the cost of a greater material expense. Advantages of 68Zn solid targetry include much greater 68Ga yields compared to liquid targets, owing to the denser 68Zn target material and superior heat transfer to the target backing that enables greater cyclotron beam currents. The much higher yields obtained with solid targetry mitigate the short half-life of 68Ga, enabling large-scale distribution of 68Ga to other PET centers surrounding a cyclotron facility.

In case of a solid target technology, like the Alceo system, Comecer has a special hot cells to handle the solid target modules:

BBS Series, Shielded Cells for Synthesis Modules.

The hot cells are big enough to accommodate the modules, moreover they have a special antiacid coating in order to avoid corrosion which increases iron contaminations in the final product and at the same time, decreases the labeling yields.

Radiolabeling with 68Ga is a single-step synthetic process that can be executed in three ways. 68Ga-radiopharmaceuticals can be produced either manually, by (semi)automated processes or by using a cold kit. A disadvantage of manual production is the manipulation of significant 68Ga activities near unshielded hands. The hands of the operator can be only protected from radioactive contamination by gloves, and from dose by extending the distance to the source of radioactivity with tweezers or tongs. Consequently, manual preparation results in high finger dose exposures for the operator. For example, the estimated absorbed body and hand dose for the manual synthesis of [68Ga]Ga-DOTA-TATE was 2.0 and 27 μSv, respectively, while compared to an automated synthesis it was 1.3 and 7.9 μSv, respectively. Additional disadvantages are inconsistent radiochemical purities and/or radiochemical yields between productions and potentially non-GMP compliant processes, which is not acceptable for translation to a clinical setting.

The key advantage of maintaining full manual control of the radiolabeling process is its usefulness for the early development of radiopharmaceuticals for research purposes. Studies regarding labeling kinetics and radiopharmaceutical stability can be performed, while keeping the hand dose low. Those labeling studies can be performed with lower radioactivity concentrations to minimize operator dose (< 100 MBq versus 1–2 GBq used for clinical application).

Even for the labelling processes a hot cell is needed. Comecer can offer different solutions:

- when a generator or a liquid target to produce 68Ga is used, and so the radioactivity levels are not so high, a Thecla is the perfect hot cell to accommodate a synthesis module;

- in case of a solid target production followed by a labeling, where we can start from 2Ci of 68Ga, a BBS hot cell is needed. The BBS Series has a higher shielding and can protect the operators from the high doses used.

The advent of commercial 68Ge/68Ga generator suppliers in multiple countries combined with PET centers implementing 68Ga cyclotron production has significantly improved the availability of 68Ga and enabled widespread use in research and the clinic. Recent high yield 68Ga cyclotron production could enable distribution to smaller communities surrounding cyclotron facilities, improving patient accessibility to diagnostic scans, provided that 66Ga/67Ga impurities in the 68Ga product are within regulatory limits. A potential advantage of distributing 68Ga activity from a cyclotron facility to smaller surrounding PET centers is lower shielding and processing space requirements associated with producing 68Ga radiopharmaceuticals on site from scratch using a 68Ge/68Ga generator.

Additionally, the widespread availability of 68Ga has resulted in its increasing use as a diagnostic radionuclide partner for nuclear medicine theranostics, highlighted by prostate cancer clinical trials using [68Ga]Ga-PSMA compounds as a diagnostic imaging agent for [177Lu]Lu-PSMA or [225Ac]Ac-PSMA therapy, and [68Ga]Ga-DOTATATE used to track [177Lu]Lu-DOTATATE or [225Ac]Ac-DOTATATE therapy of neuroendocrine tumors. Since the demand for targeted radionuclide therapies is increasing rapidly, it can be expected that the demand for 68Ga theranostic imaging agents will continue to increase.

Fill out the form to download the PDF document

Interested in the difference between isotopes and radioisotopes?

Keen to understand more about nuclear medicine?

Join us for an in-depth exploration, where we share our proven and safe solutions.